|

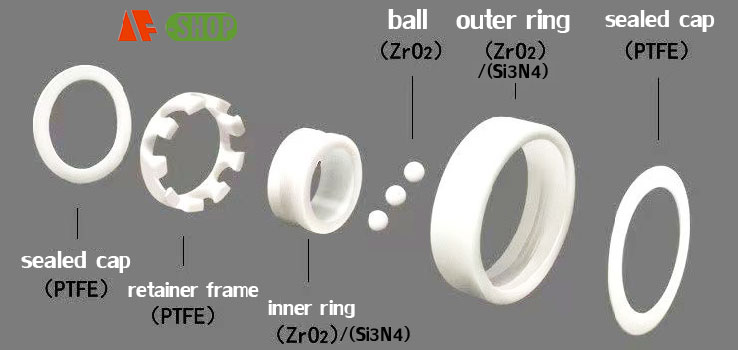

Silicon nitride (Si3N4) ceramic bearings: Compared with zirconia ceramic bearings, silicon nitride ceramic bearings are suitable for higher speeds and load capacities, as well as higher ambient temperatures. At the same time, silicon nitride ceramic bearings can also provide high-speed, high-precision, and high precision applications.The precision ceramic bearings of the rigid spindle have a maximum manufacturing accuracy of P4 to UP level.

2、 Performance advantages

Compared with steel bearings, all ceramic bearings have the following significant performance advantages:

-Corrosion resistance: All ceramic bearings can resist the erosion of corrosive environments such as strong acids, strong alkalis, inorganic and organic salts, and seawater.

High temperature resistance: All ceramic bearings have excellent high temperature resistance, a wide range of operating temperatures, and are not easily expanded due to temperature differences.

-Wear resistance: All ceramic bearings have excellent wear resistance and can maintain a long service life in high-speed and high load working environments.

-Anti magnetic and electrical insulation: All ceramic bearings are non-magnetic, therefore they have electrical insulation properties and can be used in situations where anti magnetism is required.

-Oil free self-lubricating: All ceramic bearings have self-lubricating properties, reducing the use of lubricants and lowering maintenance cost.

3、 Application Fields

The excellent performance of all ceramic bearings has enabled them to be widely used in many fields, including but not limited to:

-Aerospace: Ceramic rolling bearings have extremely excellent high-speed performance and are suitable for high-precision, high load working environments such as aerospace engines.

-Navigation: can be used in shipbuilding and other occasions that require corrosion resistance and high temperature resistance.

-Petrochemical industry: can be used in electroplating equipment, chemical machinery and other occasions that require corrosion resistance.

-Automobiles: can be used in high-temperature and high-speed running automotive components.

-Electronic devices: can be used in electronic devices that require demagnetization and high temperature resistance.

-Medical devices: can be used in medical devices that require high precision and corrosion resistance.

4、 Manufacturing process

The manufacturing process of all ceramic bearings is relatively complex, mainly including steps such as powder metallurgy molding, injection molding, and sintering. Among them, sintering process is one of the core steps in the production of pure ceramic bearings, and its quality is related to the structure and performance of the bearings.

5、 Precautions

When choosing and using all ceramic bearings, the following points should be noted:

Speed and load: Full ceramic bearings made of different materials are suitable for different speed and load conditions, and should be selected according to specific application scenarios.

-Installation and maintenance: The installation and maintenance of all ceramic bearings need to follow certain specifications to ensure the stability of their performance and service life.

-Price and Cost: The price of all ceramic bearings is relatively high, but considering their excellent performance and wide range of applications, their cost-effectiveness is still high.

In summary, all ceramic bearings have attracted much attention due to their excellent performance, wide application fields, and complex manufacturing processes. With the continuous advancement of technology and the expansion of application fields, all ceramic bearings will be more widely used in various fields Widely applicable.

|