|

All ceramic bearings are high-performance bearings, with rolling elements and inner and outer rings made of ceramic materials. The following is a detailed introduction to all ceramic bearings:

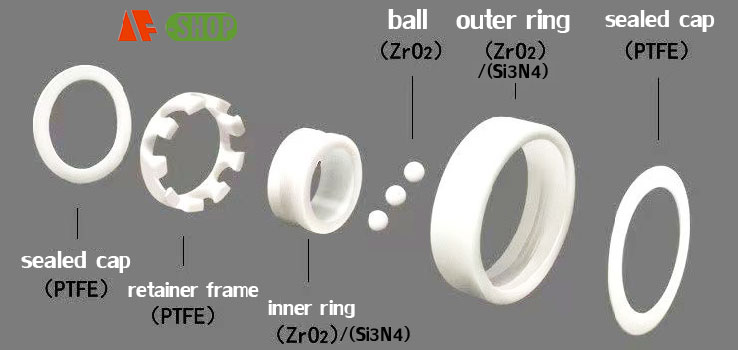

Structure of bearings (Select attachments based on actual usage--sealed cap and retainer) Years of practical experience IF company have proven:zirconia bearings or Silicon nitride (Si3N4) bearings with retainers and sealed cap typically have a high temperature resistance of about 200 degrees Celsius, while fully zirconia bearings without retainers and sealed cap have a high temperature resistance of about 500 degrees Celsius, and fully Silicon nitride (Si3N4) bearings have a high temperature resistance of about 1200 degrees Celsius,but Its disadvantages: low speed, low load. Thus providing a basis for practical selection and use.

1、 Classification and Characteristics of Materials

|

|

Silicon nitride (Si3N4) ceramic bearings: Compared with zirconia ceramic bearings, silicon nitride ceramic bearings are suitable for higher speeds and load capacities, as well as higher ambient temperatures. At the same time, silicon nitride ceramic bearings can also provide high-speed, high-precision, and high precision applications.The precision ceramic bearings of the rigid spindle have a maximum manufacturing accuracy of P4 to UP level.

2、 Performance advantages

3、 Application Fields

4、 Manufacturing process

5、 Precautions

-Price and Cost: The price of all ceramic bearings is relatively high, but considering their excellent performance and wide range of applications, their cost-effectiveness is still high. In summary, all ceramic bearings have attracted much attention due to their excellent performance, wide application fields, and complex manufacturing processes. With the continuous advancement of technology and the expansion of application fields, all ceramic bearings will be more widely used in various fields Widely applicable.

|